The rise of cloud-based control systems has revolutionized machine automation. Cloud platforms offer scalability, remote access, and valuable data insights. However, for certain situations, sole reliance on the cloud can introduce limitations. Latency, or the time it takes for data to travel between machines and the cloud, can hinder real-time decision-making and control. Additionally, constant data transmission can strain network bandwidth and raise security concerns. This is where edge computing steps in, emerging as a powerful complement to cloud-based control systems, and fundamentally reshaping the landscape of machine automation.

Edge computing decentralizes the processing power. Instead of relying solely on remote cloud servers, data is processed closer to its source – the machines themselves. This is accomplished through edge devices such as microcontrollers and industrial PCs, which collect and analyze data locally. Crucially, edge devices can still communicate with cloud platforms for data storage, advanced analytics, and visualization.

The benefits of edge computing for machine automation are significant:

- Faster Response Times: By processing critical data locally, edge computing minimizes latency. This allows for near real-time decision-making and immediate control adjustments for connected machines, optimizing performance and production processes.

- Reduced Network Bandwidth: Edge computing reduces the constant flow of data to the cloud. This not only saves on network bandwidth costs but also alleviates potential network congestion, ensuring smooth and reliable communication between machines.

- Improved Data Security: Edge computing enhances data security by keeping sensitive machine data local on edge devices. This minimizes reliance on potentially vulnerable internet connections and reduces the risk of data breaches.

The Edge in Action: Real-World Applications

Edge computing isn’t just theoretical. Let’s explore some current applications transforming machine automation across industries:

- Predictive Maintenance: Edge-based analytics can analyze sensor data from machines in real-time, identifying early signs of wear and tear. This enables proactive maintenance, preventing costly downtime and increasing machine lifespan.

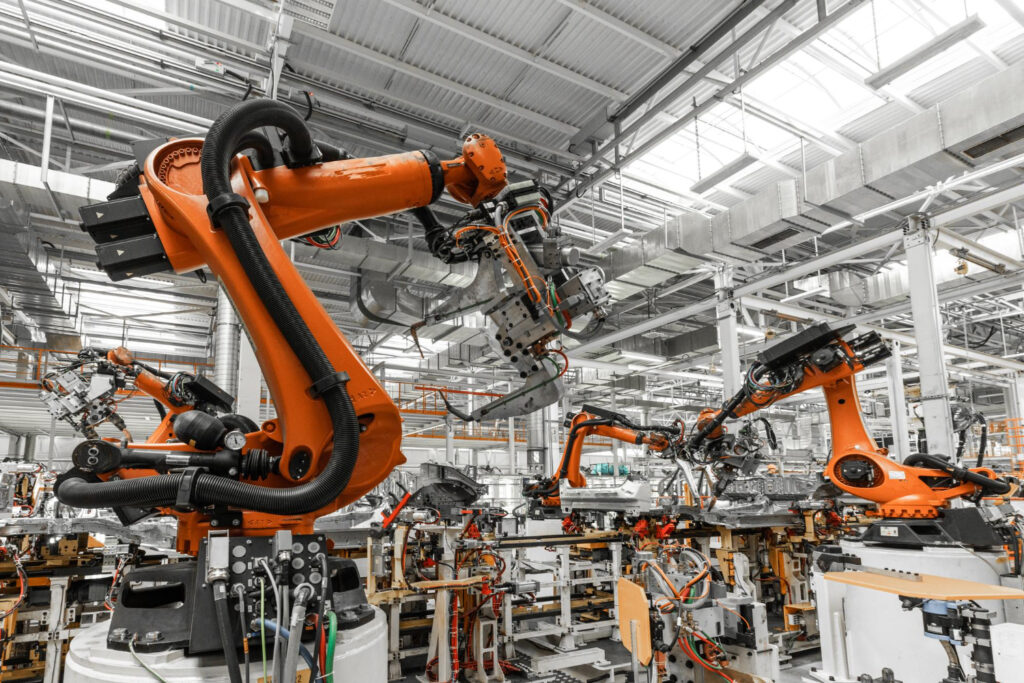

- Optimizing Robot Performance: Robots equipped with edge devices can process sensor data instantaneously. This allows for real-time adjustments to robot movements and control systems based on environmental changes and task requirements, leading to improved precision and efficiency.

- Decentralized Manufacturing: Edge computing empowers decentralized manufacturing setups. By enabling local decision-making and autonomous control for individual machines, edge computing facilitates production flexibility and adaptability in geographically distributed manufacturing environments.

The Future of Automation: A Combined Approach

The future of machine automation lies in a powerful collaboration between cloud and edge computing. Cloud platforms offer valuable data storage, advanced analytics, and visualization capabilities, while edge computing provides real-time processing power and enhanced security. By leveraging both approaches, manufacturers can unlock the full potential of machine automation, leading to increased efficiency, reduced costs, and a significant competitive edge.

Ready to explore how edge computing solutions can revolutionize your machine automation processes? Contact JHT Automation today! We offer a comprehensive suite of edge computing solutions tailored to meet the specific needs of your automation projects. Let’s discuss how edge computing can empower your business to achieve peak performance.